The Summerville HVAC Maintenance Checklist

The Summerville HVAC Maintenance Checklist That Prevents 90% of Repairs Regular HVAC maintenance prevents up to 90% of common repairs and extends system lifespan by 5-7 years. Summerville homeowners should perform monthly tasks (filter checks, vent clearing, thermostat monitoring), seasonal tasks (condensate drain treatment, outdoor unit cleaning, refrigerant line inspection), and schedule professional tune-ups twice yearly—in spring before cooling season and fall before heating season. The Lowcountry’s extreme humidity, extended cooling season, and airborne particulates demand more frequent maintenance than national guidelines suggest. A well-maintained system runs more efficiently, breaks down less often, and keeps your home comfortable year-round. Introduction: The Cheapest Repair Is the One You Never Need Here’s a number that should get your attention: 90%. That’s the percentage of HVAC repairs that could have been prevented with proper maintenance. Nine out of ten service calls we make in Summerville are for problems that didn’t have to happen. Clogged filters that caused compressors to overheat. Condensate drains that backed up and flooded ceilings. Capacitors that failed because coils were too dirty to dissipate heat. Refrigerant leaks that started as minor corrosion nobody caught. Every one of these repairs cost the homeowner hundreds—sometimes thousands—of dollars. And every one of them was preventable. At Coastal Carolina Comfort, we’ve maintained HVAC systems across the Lowcountry for over a decade. We’ve seen what neglect does to equipment in our climate. We’ve also seen homeowners who follow a simple maintenance routine go 10+ years without a single major repair. This guide gives you that routine. It’s specifically designed for Summerville’s climate—not generic advice written for somewhere with mild summers and low humidity. Follow this checklist, and you’ll dramatically reduce your repair bills, extend your system’s life, and stay comfortable no matter what the Lowcountry weather throws at you. Why Summerville Systems Need More Maintenance Before we dive into the checklist, let’s talk about why maintenance matters more here than almost anywhere else. The Extended Cooling Season In Minneapolis, an AC might run 4 months per year. In Summerville, we’re cooling 8-9 months—sometimes longer. That’s twice the operating hours, twice the wear, and twice the opportunity for problems to develop. A system that runs from April through November accumulates wear equivalent to nearly two years of operation in a milder climate. Maintenance intervals need to reflect that reality. The Humidity Factor Summerville’s average humidity hovers around 70-80% year-round. During summer mornings, it regularly exceeds 90%. This humidity: Forces your system to work harder (dehumidification uses significant energy) Creates ideal conditions for biological growth in drain lines and on coils Accelerates corrosion on electrical components and refrigerant lines Causes condensate drain clogs—one of the most common service calls we see Related: Learn how Summerville’s humidity damages HVAC systems Airborne Particulates Between pollen season (which feels like it lasts 8 months here), coastal salt air, and general Lowcountry dust, your system filters more particulates than systems in cleaner environments. Filters clog faster, coils get dirtier, and airflow restrictions develop more quickly. The Bottom Line National maintenance guidelines assume average conditions. Summerville doesn’t have average conditions—we have extreme conditions. Your maintenance routine needs to account for that. Monthly Maintenance Tasks These quick tasks take 10-15 minutes and should become habit. Do them on the same day each month—the first Saturday, the day you pay your mortgage, whatever helps you remember. 1. Check and Replace Your Air Filter This is the single most important thing you can do for your HVAC system. A clogged filter: Restricts airflow, forcing your system to work harder Causes evaporator coils to freeze Leads to compressor overheating and failure Increases energy consumption by 5-15% Reduces indoor air quality How to check: Locate your filter (return air grille, air handler, or dedicated filter slot) Remove the filter and hold it up to light If you can’t see light through it clearly, replace it If it’s visibly gray or caked with debris, replace it immediately Summerville-specific guidance: During peak cooling season (May-September), check weekly and replace every 30-45 days During shoulder seasons, check monthly and replace every 45-60 days During pollen season (spring), you may need to replace every 2-3 weeks After storms or high-wind events, check immediately Filter recommendations: Use pleated filters rated MERV 8-11 for best balance of filtration and airflow Avoid fiberglass filters (minimal filtration) and ultra-high MERV ratings (can restrict airflow) Buy filters in bulk—you’ll use 8-12 per year in Summerville 2. Clear Supply and Return Vents Blocked vents disrupt airflow balance and force your system to work harder. Monthly walkthrough: Check all supply vents (where air blows out) for obstructions Check all return vents (where air is pulled in) for blockages Move furniture, curtains, rugs, or stored items that block airflow Vacuum vent covers to remove dust buildup Ensure all vents are open (closing vents doesn’t save energy—it creates pressure imbalances) 3. Monitor Thermostat Performance Your thermostat is the brain of your HVAC system. Small issues here cause big problems. Monthly checks: Verify the display is clear and responsive Confirm the temperature reading seems accurate (compare to a separate thermometer) Check that the system responds when you adjust settings Replace batteries annually (or when the low battery indicator appears) For smart thermostats, ensure WiFi connection is stable Warning signs: Temperature swings greater than 2-3 degrees from setpoint System not responding to setting changes Blank or flickering display “Auxiliary heat” running frequently (for heat pump systems) 4. Listen and Observe Your system tells you when something’s wrong—if you’re paying attention. Monthly awareness check: Listen for unusual noises (grinding, squealing, banging, clicking) Notice any unusual odors from vents Feel for weak airflow or temperature inconsistencies Watch for water around the indoor unit Check for ice on refrigerant lines (visible at the outdoor unit) Related: Know the 5 warning signs your AC is about to break down Seasonal Maintenance Tasks These tasks should be performed quarterly or at the start of each season. They’re more involved than monthly tasks but still manageable for most homeowners. Spring: Prepare for Cooling Season Complete these tasks in

HVAC Repair vs. Replacement

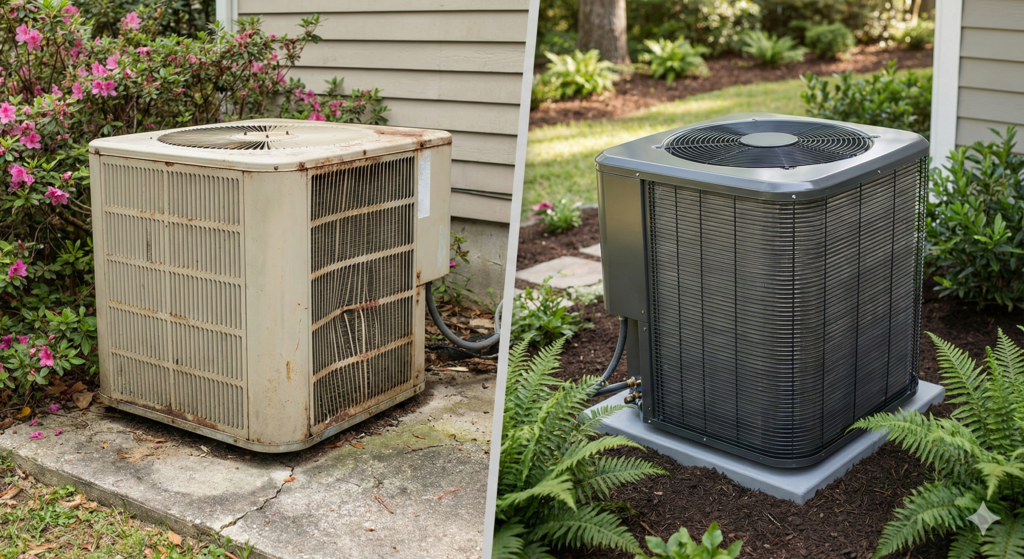

HVAC Repair vs. Replacement: A Summerville Homeowner’s Decision Guide Deciding between HVAC repair and replacement comes down to four key factors: the cost of repair relative to replacement (use the 50% rule—if repairs exceed half the cost of a new system, replace), the age of your equipment (systems over 15 years old are usually better replaced), refrigerant type (R-22 systems should be replaced due to phase-out costs), and repair frequency (multiple repairs per year signal it’s time). Summerville homeowners should also factor in energy efficiency gains, available rebates, and the demanding Lowcountry climate that shortens system lifespans compared to national averages. The Question Every Homeowner Dreads Your HVAC technician just delivered the news: your system needs a major repair. Maybe it’s a compressor. Maybe it’s a coil leak. Whatever it is, the number has four digits, and now you’re facing the question every Summerville homeowner eventually confronts. Do I fix it, or do I replace the whole thing? It’s not an easy decision. Repair feels like the cheaper option—until you’re repairing again six months later. Replacement feels like the responsible choice—until you see the price tag. And everyone from your neighbor to your brother-in-law has an opinion. At Coastal Carolina Comfort, we’ve guided thousands of Lowcountry homeowners through this exact decision. We’ve seen people waste money repairing systems that should have been replaced years ago. We’ve also seen people replace perfectly good equipment because someone talked them into it. This guide will give you the framework to make the right decision for your situation—not based on sales pressure, but on facts, math, and what actually makes sense for your home and budget. The 50% Rule: Your Starting Point The most reliable rule of thumb in the HVAC industry is simple: If the repair costs more than 50% of what a new system would cost, replace instead of repair. Here’s why this works: The Math Behind the Rule Let’s say a new HVAC system for your Summerville home costs $8,000 installed. Using the 50% rule: Repair cost under $4,000: Repair is likely the better value Repair cost over $4,000: Replacement makes more financial sense But this isn’t just about today’s repair. It’s about what comes next. A system that needs a $3,500 repair today is likely to need another significant repair within 1-2 years. That’s the nature of aging equipment—when major components fail, others are usually close behind. So that $3,500 repair might actually cost you $3,500 + $1,200 + $800 over the next two years. Suddenly you’ve spent $5,500 and still have an old, inefficient system. When to Adjust the Rule The 50% rule is a starting point, not an absolute. Adjust based on: System age: For systems under 8 years old, you might stretch to 60-70% before replacing—they likely have more good years ahead. For systems over 12 years old, consider replacing at 30-40% of replacement cost. Repair history: If this is the first major repair on a well-maintained system, lean toward repair. If it’s the third repair this year, lean toward replacement regardless of cost. Component involved: Some repairs (capacitor, contactor, fan motor) are normal wear items that don’t indicate broader system failure. Others (compressor, evaporator coil) often signal the beginning of the end. The Age Factor: How Old Is Too Old? System age is the second most important factor in your decision. Average HVAC Lifespan National average: 15-20 years with proper maintenance Summerville reality: 12-16 years is more typical Why the difference? Our systems work harder. A Summerville AC runs 8-9 months per year, often 12+ hours per day during summer. Compare that to a system in Minneapolis that might run 4 months per year. More operating hours means faster wear. Age-Based Decision Framework Under 8 years old: Almost always repair unless the cost exceeds 50% of replacement. These systems have significant life remaining. 8-12 years old: Evaluate carefully. Major repairs may be worthwhile, but start planning for eventual replacement. This is a good time to begin saving. 12-15 years old: Lean toward replacement for major repairs. The system is in its final years, and repair money is often better invested in new equipment. Over 15 years old: Replace for any significant repair. Even if the repair is relatively affordable, you’re likely facing additional failures soon. The efficiency gains alone often justify replacement. The Warranty Consideration Most HVAC systems come with: 5-10 year compressor warranty 5-10 year parts warranty 1 year labor warranty (sometimes extended by the installer) If your system is still under warranty, repair almost always makes sense—your out-of-pocket cost is limited to labor and any non-covered parts. Check your paperwork or call your installer to verify warranty status before making any decisions. The R-22 Refrigerant Problem If your system uses R-22 refrigerant (also called Freon or HCFC-22), this single factor may make your decision for you. What Happened to R-22 R-22 was the standard air conditioning refrigerant for decades. However, due to its ozone-depleting properties, the EPA phased it out: 2010: No new R-22 systems could be manufactured 2020: Production and import of R-22 banned entirely This means all R-22 available today is either recycled or reclaimed from decommissioned systems. Supply is limited and shrinking every year. The Cost Impact R-22 prices have skyrocketed: 2010: Approximately $10-15 per pound 2020: Approximately $50-75 per pound 2026: $100-200+ per pound depending on availability A typical residential AC system holds 6-12 pounds of refrigerant. If your R-22 system develops a leak, you’re looking at: Leak repair: $200-$1,000+ depending on location Refrigerant recharge: $600-$2,400+ for a full charge Total cost: Often $1,000-$3,000+ for a single repair And here’s the kicker—if it leaks once, it will likely leak again. You could face these costs repeatedly. How to Know If You Have R-22 Check the data plate on your outdoor unit. Look for: “R-22” or “HCFC-22” = R-22 system (consider replacement) “R-410A” or “Puron” = Modern refrigerant (repair may make sense) If your system was installed before 2010, it almost certainly uses R-22. Systems installed 2010-2015 could be either. Systems installed after 2015 are virtually all R-410A. Our Recommendation If you have an R-22 system that needs any refrigerant-related repair, replace

Emergency HVAC Repair in Summerville

Emergency HVAC Repair in Summerville: What to Do When Your AC Dies at 2 AM When your AC fails unexpectedly in Summerville, stay calm and follow these steps: First, check your thermostat settings and batteries, then inspect your circuit breaker for tripped switches, and finally examine your air filter for severe clogs. If these quick fixes don’t restore cooling, turn off the system to prevent further damage and call for emergency HVAC service. While waiting, close blinds, open interior doors, and use fans to circulate air. True HVAC emergencies include complete system failure during extreme heat, burning smells, gas odors, or water actively flooding your home. 2 AM, 85 Degrees, and Dead Silence You wake up sweating. The house feels wrong—heavy, still, suffocating. You check the thermostat: 85°F and climbing. The AC isn’t running. It’s 2 AM on a July night in Summerville, and your air conditioner has officially quit. First things first: take a breath. We know that moment of panic. After more than a decade of emergency calls across the Lowcountry, we’ve talked hundreds of homeowners through this exact situation. And here’s what we’ve learned—most people don’t know what to do, what to check, or when a situation truly requires emergency service. This guide will walk you through exactly what to do when your AC dies unexpectedly, how to stay safe and relatively comfortable while you wait for help, and how to know whether you’re dealing with a true emergency or something that can wait until morning. Let’s get you through this. Step 1: Don’t Panic—Troubleshoot First Before you pick up the phone, run through these quick checks. You’d be surprised how often a “dead” AC is actually a simple fix. Check Your Thermostat It sounds obvious, but start here: Verify the settings: Is it set to “cool”? Is the temperature set below the current room temperature? We’ve seen thermostats accidentally bumped to “heat” or “off” more times than we can count. Check the batteries: Many thermostats run on batteries, and when they die, so does communication with your system. If your thermostat screen is blank or dim, swap in fresh batteries. Look for error codes: Smart thermostats and some programmable models display error codes when something’s wrong. Check your manual or do a quick phone search for what the code means. Try a reset: Turn the thermostat off completely, wait 30 seconds, then turn it back on. Sometimes that’s all it takes. Inspect Your Circuit Breaker Your HVAC system typically uses two breakers—one for the indoor air handler and one for the outdoor condenser. Head to your electrical panel and look for: Tripped breakers: A tripped breaker sits in the middle position between “on” and “off,” or may show a red indicator. If you find one, flip it fully to “off,” then back to “on.” Multiple trips: If the breaker trips again immediately or within a few minutes, stop. Repeated tripping indicates an electrical problem that needs professional diagnosis. Don’t keep resetting it. Labeled breakers: Look for labels like “AC,” “HVAC,” “Air Handler,” or “Condenser.” If your panel isn’t labeled, the HVAC breakers are typically 20-40 amp double breakers. Check Your Air Filter A severely clogged filter can cause your system to overheat and shut down as a safety measure. Locate your filter: Usually found in the return air grille, at the air handler, or in a filter slot in your ductwork. Assess the condition: If you can’t see light through it, or if it’s visibly caked with dust and debris, it’s overdue for replacement. Replace if necessary: Put in a fresh filter and give your system 15-20 minutes to reset before trying to restart. Inspect the Outdoor Unit If it’s safe to go outside (and you have a flashlight), take a quick look at your condenser: Is it running? If the indoor fan runs but the outdoor unit is silent, the problem is likely outside—possibly a capacitor, contactor, or compressor issue. Is it blocked? Check for debris, overgrown vegetation, or anything restricting airflow around the unit. Is ice present? Ice on the refrigerant lines or the unit itself indicates a problem—usually low refrigerant or airflow restriction. If you see ice, turn the system off and call for service. Is the disconnect pulled? There’s an electrical disconnect box near your outdoor unit. Make sure it hasn’t been accidentally switched off. Step 2: Determine If It’s a True Emergency Not every AC failure at night requires emergency service. Here’s how to assess your situation: True HVAC Emergencies—Call Now Burning smell or visible smoke: Turn off your system immediately at the thermostat AND the breaker. This could indicate an electrical fire. If you see smoke or the smell is strong, evacuate and call 911 first, then your HVAC company. Gas smell (rotten eggs/sulfur): If you have a gas furnace and smell gas, leave your home immediately. Don’t flip any switches or use your phone inside. Call your gas company’s emergency line from outside, then call 911 if needed. Water actively flooding: If your condensate drain has backed up and water is pouring into your home, you need to stop the damage. Turn off the system and call for emergency service to prevent ceiling collapse, floor damage, or electrical hazards. Extreme heat with vulnerable occupants: If temperatures are dangerous (90°F+) and you have infants, elderly family members, people with medical conditions, or pets that can’t be relocated, this becomes a health emergency. Complete failure during heat advisory: When the National Weather Service issues a heat advisory for the Summerville area and your AC is completely non-functional, waiting until morning could be dangerous. Urgent But Can Wait Until Morning System not cooling efficiently: If the AC runs but doesn’t cool well, you can likely make it through the night with fans and open windows (if outdoor temps allow). Intermittent operation: A system that cycles on and off or works sometimes is frustrating but not dangerous. Document what’s happening to help your technician diagnose faster. Strange noises without other symptoms: Grinding, squealing, or banging sounds warrant prompt attention but don’t require a 3 AM service call unless accompanied by burning smells or system

How Summerville’s Humidity Destroys HVAC Systems

How Summerville’s Humidity Destroys HVAC Systems (And How to Fight Back) Summerville’s high humidity—averaging 70-80% year-round—forces HVAC systems to work significantly harder than in drier climates. Excess moisture causes evaporator coil corrosion, refrigerant line damage, condensate drain clogs, and accelerated wear on compressors and fan motors. Lowcountry homeowners can protect their systems by maintaining proper airflow, scheduling regular maintenance, ensuring adequate drainage, and considering whole-home dehumidification solutions. Without proactive care, humidity cuts years off your system’s lifespan and drives up energy costs. The Invisible Enemy in Your Home If you’ve lived in Summerville for more than one summer, you know the humidity isn’t just uncomfortable—it’s oppressive. Step outside in July and the air wraps around you like a warm, wet blanket. Your glasses fog up walking from the car to the front door. Your hair does things you didn’t ask it to do. But here’s what most homeowners don’t realize: that same humidity is waging a slow war on your HVAC system every single day. At Coastal Carolina Comfort, we’ve spent over a decade repairing and replacing systems across the Lowcountry. And we can tell you this with certainty—humidity is the silent killer of HVAC equipment in our region. Systems that should last 18-20 years are giving out at 12. Units that ran efficiently for years suddenly can’t keep up. The good news? Once you understand how humidity attacks your system, you can fight back. Let’s break down exactly what’s happening inside your HVAC—and what you can do about it. Why Summerville’s Humidity Is So Hard on HVAC Systems The Numbers Don’t Lie Summerville averages 70-80% relative humidity throughout the year. During summer months, it’s not uncommon to see 90%+ humidity in the early morning hours. Compare that to Phoenix at 20-30% or Denver at 40-50%, and you start to understand the challenge. Your air conditioner wasn’t just designed to cool air—it’s designed to remove moisture. In fact, dehumidification accounts for roughly 30% of your AC’s workload in a humid climate. In Summerville, that number climbs even higher. The Double Duty Problem Every time your AC runs, it’s doing two jobs simultaneously: Cooling the air by absorbing heat through the evaporator coil Dehumidifying by condensing moisture out of the air onto that same coil In drier climates, the cooling job dominates. In Summerville, your system spends enormous energy just wringing water out of the air. This means longer run times, higher energy bills, and accelerated wear on every component. What “Feels Like” Temperature Really Means When the weather app says it’s 88°F but “feels like” 102°F, that’s humidity at work. Your body cools itself through sweat evaporation—but when the air is already saturated with moisture, that sweat can’t evaporate efficiently. The same principle applies to your home. High humidity makes 74°F feel stuffy and uncomfortable, so you crank the thermostat down to 70°F. Now your system runs even longer, works even harder, and wears out even faster. 5 Ways Humidity Damages Your HVAC System 1. Evaporator Coil Corrosion and Buildup Your evaporator coil is ground zero for humidity removal. As warm, moist air passes over the cold coil, water vapor condenses into liquid—just like condensation on a cold glass of sweet tea. In Summerville’s humidity, your coil handles gallons of water daily. This constant moisture exposure causes: Corrosion: The coil’s aluminum or copper fins gradually corrode, reducing heat transfer efficiency and eventually causing refrigerant leaks. Biological buildup: The perpetually damp environment creates ideal conditions for organic growth on and around the coil. This buildup insulates the coil, forcing your system to work harder. It also restricts airflow and can cause unpleasant odors. Note: If you suspect biological contamination in your HVAC system, we recommend consulting with a qualified specialist who can properly assess and remediate the situation. Dirt accumulation: Moisture makes the coil sticky, trapping dust, pollen, and debris that would otherwise pass through. This layer of gunk further reduces efficiency. 2. Condensate Drain Line Clogs All that moisture your AC removes has to go somewhere. It drips into a drain pan and flows out through a condensate drain line—typically a PVC pipe that exits near your outdoor unit or into a floor drain. In humid Summerville, this drain line handles far more water than systems in drier climates. The constant moisture flow creates a perfect environment for: Algae growth inside the line Organic slime buildup Debris accumulation at connection points When the drain clogs, water backs up into the drain pan. If the pan overflows, you’re looking at water damage to ceilings, walls, and floors. Many systems have a safety float switch that shuts down the AC when water backs up—which means you come home to a hot house and no idea why. Pro tip: We see more condensate drain clogs in Summerville between May and September than any other issue. A $15 preventive treatment can save you a $150+ service call. 3. Compressor Strain and Premature Failure Your compressor is the heart of your AC system—and the most expensive component to replace. It’s responsible for pressurizing refrigerant and circulating it through the system. Humidity increases compressor workload in several ways: Extended run times: When your system runs longer to handle moisture removal, the compressor runs longer too. More operating hours means more wear. Higher head pressure: Humid conditions can increase the pressure your compressor works against, generating more heat and stress on internal components. Short-cycling risk: If humidity causes coil icing or other issues, the system may short-cycle—turning on and off frequently. Each startup is the hardest moment for a compressor, so frequent cycling dramatically accelerates wear. A compressor replacement typically costs $1,500-$3,000 including labor. In many cases, it makes more sense to replace the entire system at that point. 4. Ductwork Deterioration Your ductwork is often the forgotten component of your HVAC system—out of sight in attics, crawl spaces, and wall cavities. In Summerville’s humidity, those hidden spaces become problem zones. Condensation on ducts: When cold air flows through ducts in a hot, humid attic or crawl space, condensation forms on the outside of the ducts.

5 Warning Signs Your AC Is About to Break Down

5 Warning Signs Your AC Is About to Break Down (And What Summerville Homeowners Can Do) An air conditioner rarely fails without warning. The five signs your AC is about to break down are strange noises like grinding or squealing, weak or warm airflow, unusual odors from your vents, frequent on-off cycling, and unexplained spikes in your energy bills. Summerville homeowners who catch these warning signs early can often avoid emergency repairs and costly replacements. If you notice any of these symptoms, scheduling a professional inspection promptly can save you hundreds—or even thousands—of dollars. Your AC Is Talking. Are You Listening? Here in Summerville, we ask a lot of our air conditioners. Between the sweltering summers and humidity thick enough to swim through, your HVAC system works overtime from April through October—and sometimes beyond. The good news? Your AC usually gives you a heads-up before it throws in the towel. The bad news? Most folks don’t recognize the warning signs until they’re fanning themselves with a magazine and calling for emergency service. At Coastal Carolina Comfort, we’ve seen it all. After more than a decade serving Summerville and the surrounding Lowcountry, we’ve learned that the homeowners who know what to look (and listen) for are the ones who avoid the worst breakdowns. Let’s walk through the five warning signs that your air conditioner is struggling—and what you can do about each one. 1. Strange Noises Coming From Your Unit A healthy air conditioner hums along quietly. When it starts making noises that sound like a complaint, it’s time to pay attention. What You Might Hear Grinding or metal-on-metal sounds usually point to a problem with the blower motor or fan bearings. These components wear down over time, especially in systems that run as hard as ours do in the Summerville heat. Squealing or screeching often indicates a worn belt or motor bearing issue. While belts are less common in newer systems, plenty of Summerville homes—especially in historic downtown and older neighborhoods—still have units with belt-driven components. Clicking sounds at startup or shutdown are normal. Constant clicking during operation is not. This typically signals an electrical issue or a failing thermostat relay. Banging or clanking suggests something has come loose inside the unit. This could be a disconnected fan blade, a loose component, or debris that found its way into the system. Bubbling or hissing points to a refrigerant leak. This is one you don’t want to ignore—refrigerant issues affect both your comfort and your system’s longevity. What Summerville Homeowners Should Do Don’t crank up the TV to drown out the noise. If your AC is making sounds it didn’t make last month, turn off the system and call for an inspection. Running a struggling unit often turns a minor repair into a major one. A quick diagnostic visit can identify whether you’re looking at a simple fix—like tightening a loose component—or something that needs more attention. Either way, you’ll sleep better knowing what you’re dealing with. Related: If you’re in the Knightsville or Oakbrook areas, our technicians know the common issues in your neighborhoods’ housing stock. Learn more about HVAC repair services in your area. 2. Weak Airflow or Warm Air From Your Vents You set the thermostat to 72, but your house feels like 80. Or maybe the air coming from your vents feels more like a whisper than a breeze. Both scenarios signal trouble. Common Causes of Weak Airflow Clogged air filters are the most common culprit—and the easiest to fix. In Summerville’s dusty, pollen-heavy environment, filters clog faster than the manufacturer’s recommendations suggest. We recommend checking yours monthly during peak cooling season. Blocked or leaky ductwork prevents conditioned air from reaching your rooms. Older Summerville homes, particularly those built before the 1990s, often have ductwork that’s deteriorated, disconnected, or was never properly sealed in the first place. Failing blower motor can’t push air through your system effectively. You might notice the airflow weakening gradually over weeks or months. Frozen evaporator coil restricts airflow significantly. This often results from low refrigerant, poor airflow (see: clogged filters), or dirty coils. Why Is My AC Blowing Warm Air? If the air isn’t just weak but actually warm, you’re likely dealing with: Low refrigerant levels from a leak somewhere in the system Compressor failure, which is the heart of your AC Thermostat issues causing miscommunication between what you set and what the system does Electrical problems preventing the outdoor unit from running properly What Summerville Homeowners Should Do Start with the filter. If it’s dirty, replace it and give your system 30 minutes to recover. Still having issues? Check your outdoor unit—make sure it’s running and clear of debris, leaves, or overgrown landscaping. If the problem persists, you need professional eyes on it. Weak airflow and warm air often indicate issues that worsen quickly in our Lowcountry heat. 3. Unusual Odors From Your Vents Your air conditioner should produce one thing: cool, clean air. If you’re smelling something funky, your system is telling you something’s wrong. Decoding the Smells Musty or stale odors typically indicate moisture buildup somewhere in your system or ductwork. Summerville’s humidity creates ideal conditions for biological growth in HVAC systems. This is particularly common in systems that don’t run consistently or in homes with poor drainage around the indoor unit. Note: If you suspect biological growth in your system, we recommend consulting with a specialist who can properly assess and address the situation. Our team can inspect your HVAC equipment and refer you to qualified professionals if needed. Burning or electrical smells demand immediate attention. Turn off your system right away. This could indicate overheating components, electrical issues, or even a potential fire hazard. Rotten egg or sulfur smells near your HVAC system could indicate a natural gas leak if you have a gas furnace. Leave your home immediately and call your gas company. Chemical or sweet smells might point to a refrigerant leak. Refrigerant exposure isn’t something to mess with—it’s harmful to breathe and means your system is losing its ability to cool. What Summerville Homeowners Should Do For musty odors, start by

Heating Repair Scams: How Summerville Homeowners Can Protect Themselves from Dishonest Contractors

Heating Repair Scams: How Summerville Homeowners Can Protect Themselves from Dishonest Contractors Heating repair scams typically involve fake diagnoses (especially the “cracked heat exchanger” scare), bait-and-switch pricing, unnecessary repairs, and high-pressure sales tactics designed to rush you into expensive decisions. Protect yourself by getting second opinions on major repairs, verifying contractor licensing through South Carolina’s LLR website, checking reviews and BBB ratings, and never authorizing work without a written estimate. Legitimate heating repair companies explain problems clearly, provide documentation, and give you time to decide. If a technician pressures you to replace your entire system immediately or demands cash payment, those are major red flags requiring a second opinion. Why Heating Repair Scams Are So Effective Scammers exploit a perfect storm of circumstances: You’re vulnerable. When your heat fails in January, you’re cold, stressed, and desperate for a solution. Rational decision-making suffers. You lack expertise. Most homeowners can’t evaluate whether a diagnosis is legitimate. You’re trusting someone you just met to tell you the truth about complex equipment. The stakes feel high. Heating problems can involve safety concerns (carbon monoxide, gas leaks) that make you afraid to question recommendations. Time pressure is real. You need heat now, not next week. This urgency makes you susceptible to pressure tactics. Dishonest contractors know all of this—and they use it against you. Understanding common scams helps you recognize them before you become a victim. The “Cracked Heat Exchanger” Scam This is the most common and most lucrative heating repair scam. Here’s how it works: The Setup A technician arrives for routine maintenance, a minor repair, or a “free inspection” offer. During the visit, they examine your furnace and deliver alarming news: “I found a crack in your heat exchanger. This is very dangerous—carbon monoxide could be leaking into your home right now. You need to stop using this furnace immediately.” The Fear Factor Heat exchanger cracks are a legitimate safety concern. A cracked heat exchanger can leak carbon monoxide—an odorless, colorless gas that kills hundreds of Americans annually. The technician is counting on you knowing this. They may show you: Photos (possibly from another furnace or the internet) A video scope image (often misrepresented or from another job) “Evidence” of carbon monoxide (using a detector held near the furnace) The Pressure With fear established, the pressure begins: “I can’t in good conscience leave this running. Your family is at risk. We need to shut this down today.” “The heat exchanger can’t be repaired—you need a new furnace. Fortunately, I can get a crew here tomorrow.” “If you sign today, I can give you a discount. Otherwise, the price goes up.” The Reality Heat exchanger cracks do occur—but they’re far less common than scammers claim. Many “cracks” are actually: Normal seams or welds in the metal Surface discoloration or rust Expansion joints designed into the exchanger Completely fabricated Legitimate diagnosis requires: Visual inspection with proper lighting Sometimes specialized cameras or dye testing Combustion analysis measuring actual CO levels Documentation you can verify How to Protect Yourself Don’t panic. A cracked heat exchanger is serious but rarely an immediate emergency. You have time to verify the diagnosis. Ask for documentation. Request photos or video of the actual crack on your actual furnace. Ask where specifically the crack is located. Get a second opinion. Before authorizing replacement, have another company inspect the furnace. A legitimate crack will be found by both technicians. Check CO levels yourself. If you have carbon monoxide detectors (you should), check their readings. Plug-in detectors with digital displays show current levels. Verify the company. Is this a reputable local company or someone who showed up offering a “free inspection”? The Bait-and-Switch Pricing Scam This scam lures you with low prices, then inflates costs once work begins. How It Works The bait: You see an advertisement or receive a quote for an attractively low price: “$49 furnace tune-up!” “Heating repair starting at $99!” “Free diagnostic with any repair!” The switch: Once the technician arrives and begins work, the price escalates: “The $49 tune-up doesn’t include the combustion analysis—that’s another $150.” “I found several problems. The $99 was just for the service call. The actual repairs will be $800.” “The diagnostic is free, but the part you need costs $400, and labor is $300.” Red Flags Prices dramatically lower than competitors Vague descriptions of what’s included “Starting at” pricing without clear parameters Refusal to provide written estimates before work begins Costs that escalate significantly once technician is on-site How to Protect Yourself Get detailed written estimates before any work begins. The estimate should specify: Diagnostic/service call fee Specific repairs recommended Parts costs Labor costs Total price Ask “what’s included” when scheduling. If the answer is vague, that’s a warning sign. Compare multiple quotes. If one quote is dramatically lower than others, ask why. Legitimate companies have similar cost structures. Don’t feel obligated. A technician in your home doesn’t mean you must authorize their repairs. You can pay the diagnostic fee and get a second opinion. The Unnecessary Repair Scam Some technicians recommend repairs you don’t actually need. Common Unnecessary Repair Claims “Your capacitor is weak.” Capacitors do fail, but “weak” is subjective. Some technicians replace functional capacitors as a revenue generator. “You need a new thermostat.” Thermostats rarely fail completely. Many “thermostat problems” are actually wiring issues, dead batteries, or user error. “Your refrigerant is low.” (Heat pumps) Refrigerant doesn’t deplete naturally—low levels indicate a leak. Adding refrigerant without fixing the leak is a temporary (and expensive) bandage. “All these parts are worn and should be replaced.” Preventive replacement has some merit, but replacing multiple functional parts is often unnecessary. How to Protect Yourself Ask questions: What specifically is wrong with this part? What happens if I don’t replace it? How urgent is this repair? Can you show me the problem? Understand the diagnosis. A legitimate technician can explain the problem in terms you understand. Vague explanations or technical jargon designed to confuse you are red flags. Get a second opinion on expensive repairs. If the diagnosis is legitimate, another technician will confirm it. Request the old parts. For replaced components, ask to see (or keep) the

Heating Maintenance Guide: How to Keep Your Summerville Home Warm and Your System Running Smoothly

Heating Maintenance Guide: How to Keep Your Summerville Home Warm and Your System Running Smoothly Annual professional heating maintenance extends your system’s lifespan by 5+ years, reduces repair costs by up to 40%, and keeps your energy bills in check. For Summerville homeowners, the best time to schedule maintenance is early fall—September or October—before you need your heating system regularly. Professional maintenance includes inspection of safety controls, cleaning of critical components, testing of electrical connections, and verification of proper operation. Between professional visits, homeowners should change air filters monthly, keep vents clear, and address unusual noises or performance changes promptly. This combination of professional and DIY maintenance keeps your heating system reliable for years. Why Heating Maintenance Matters Your heating system is one of the most expensive and essential components of your home. Yet many homeowners ignore it until something breaks. Think of maintenance like oil changes for your car. You could skip them and your car would run—for a while. But eventually, the lack of maintenance catches up with you in the form of expensive repairs or premature engine failure. Heating systems work the same way. Regular maintenance: Extends Equipment Lifespan Well-maintained systems last significantly longer: System Type Without Maintenance With Annual Maintenance Gas furnace 12–15 years 18–22 years Heat pump 8–12 years 12–16 years Electric furnace 15–20 years 22–28 years That’s 4–6 extra years of service from equipment costing $5,000–$15,000 to replace. Reduces Repair Costs Small problems caught during maintenance cost far less to fix than emergency repairs: A dirty flame sensor cleaned during a tune-up: $0 (included in maintenance) Same flame sensor causing repeated ignition failures: $150–250 service call Worn belt identified and replaced during maintenance: $50–100 Same belt breaking and damaging blower motor: $400–700 Studies show maintained systems require 40% fewer repairs than neglected ones. Maintains Efficiency Heating systems lose efficiency as components get dirty and wear: Dirty burners don’t burn fuel completely Clogged filters restrict airflow Dirty coils transfer heat poorly Worn parts create friction and resistance A system that was 95% efficient when new might operate at 80% efficiency after years of neglect. That 15% difference shows up directly in your energy bills. Ensures Safety Heating systems—especially gas furnaces—can develop dangerous conditions: Cracked heat exchangers leak carbon monoxide Faulty gas valves create leak risks Electrical problems cause fire hazards Failed safety controls don’t protect you Professional maintenance includes safety checks that protect your family. Preserves Warranty Coverage Most manufacturer warranties require annual professional maintenance. Skip it, and you may void your warranty—leaving you responsible for repairs that would otherwise be covered. Check your warranty documentation. Many require: Annual professional inspection Documentation of service performed Use of licensed contractors What Professional Heating Maintenance Includes A thorough professional tune-up covers far more than most homeowners realize. Here’s what should happen during a maintenance visit: Safety Inspection For all systems: Carbon monoxide testing in the equipment area and living spaces Inspection of flue pipe and venting (gas systems) Verification of safety control operation Electrical connection inspection for damage or overheating Gas leak check (gas systems) Why it matters: Safety issues often develop gradually and aren’t obvious until they become dangerous. Professional inspection catches them early. Thermostat Evaluation Verify accurate temperature reading Test heating cycle initiation and termination Check programming and settings Calibrate if necessary Test battery backup (if applicable) Why it matters: A thermostat that’s off by even a few degrees affects comfort and efficiency. Air Filter Assessment Inspect current filter condition Verify correct filter size and type Replace if needed Discuss optimal replacement schedule for your home Why it matters: The filter affects everything—airflow, efficiency, equipment wear, and air quality. Electrical System Inspection Test voltage and amperage Inspect wiring for damage, corrosion, or loose connections Test capacitors Check contactor condition Verify proper grounding Why it matters: Electrical problems cause component failures and create fire hazards. Gas Furnace-Specific Checks Burner inspection and cleaning: Remove and inspect burners Clean burner ports Check for rust, cracks, or damage Verify proper flame pattern and color Heat exchanger inspection: Visual inspection for cracks, rust, or separation Check for carbon monoxide leakage Assess overall condition and remaining life Ignition system: Clean flame sensor Test ignitor operation Verify proper ignition sequence Check pilot assembly (older systems) Gas valve and supply: Test gas pressure Check valve operation Inspect gas line connections Verify proper combustion air supply Venting system: Inspect flue pipe for damage, corrosion, or blockage Verify proper draft Check connections and seals Ensure proper termination outside Heat Pump-Specific Checks Outdoor unit inspection: Clean condenser coil Inspect fan blade and motor Check for debris accumulation Verify proper clearance around unit Inspect for physical damage or corrosion Refrigerant system: Check refrigerant charge Inspect for leaks Test pressures Verify proper superheat and subcooling Defrost system: Test defrost cycle initiation Verify proper defrost operation Check defrost timer or control board Reversing valve: Test operation in both heating and cooling modes Listen for proper switching Check for refrigerant bypass Auxiliary heat: Test electric heat strips Verify proper staging Check sequencer operation Blower and Air Handler For all systems: Inspect blower wheel for dirt and damage Check blower motor operation and amperage Lubricate motor bearings (if applicable) Test airflow Inspect belt condition and tension (belt-drive systems) Clean evaporator coil (if accessible) Check condensate drain and pan Why it matters: The blower moves all the air through your system. Problems here affect heating, cooling, and air quality. System Operation Test After completing all inspections and adjustments: Run complete heating cycle Verify proper temperature rise Check for unusual noises or vibrations Confirm thermostat satisfaction Test safety shutdown sequences DIY Maintenance: What Homeowners Can Do Between professional visits, these tasks keep your system running well: Monthly: Air Filter Check This is the single most important thing you can do for your heating system. How to check: Locate your filter (return vent, air handler, or furnace) Remove the filter Hold it up to light If you can’t see light through it, replace it How often to replace: Basic fiberglass filters: Every 30 days Pleated filters: Every 60–90 days High-efficiency

Emergency Heating Repair: What Summerville Homeowners Need to Know When the Heat Goes Out

Emergency Heating Repair: What Summerville Homeowners Need to Know When the Heat Goes Out When your heating fails during cold weather, the first priority is safety—check for gas leaks and carbon monoxide, then focus on keeping your family warm while arranging repairs. True heating emergencies include complete heating failure when temperatures drop below 40°F, gas odors or carbon monoxide detector alarms, and situations where vulnerable family members (infants, elderly, or those with health conditions) are at risk. For emergency heating repair in Summerville, expect to pay a premium for after-hours service, but don’t let cost concerns delay action when safety is at stake. Preparation before emergencies occur makes handling them far less stressful. What Qualifies as a Heating Emergency? Not every heating problem is an emergency. Understanding the difference helps you respond appropriately—and avoid paying emergency rates for situations that can wait. True Emergencies: Act Immediately Gas smell or suspected gas leak If you smell rotten eggs or sulfur (the odorant added to natural gas): Don’t operate any electrical switches, lights, or appliances Don’t use your phone inside the house Don’t start your car in an attached garage Get everyone out of the house immediately Call your gas company’s emergency line from outside or a neighbor’s home Don’t return until the gas company clears your home Gas leaks can cause explosions and are life-threatening. This is a 911-level emergency. Carbon monoxide detector alarm If your CO detector alarms: Get everyone out immediately—including pets Call 911 from outside Don’t re-enter until emergency responders clear the home Seek medical attention if anyone has symptoms (headache, dizziness, nausea, confusion) Carbon monoxide is odorless and colorless. Trust your detector—it exists to save your life. Complete heating failure in freezing temperatures When temperatures drop below 32°F and your heating system fails completely: Pipes can freeze within hours, leading to burst pipes and water damage Vulnerable family members face hypothermia risk The situation worsens the longer it continues This warrants emergency service, even at premium rates. Vulnerable household members at risk Even in moderately cold weather (40s–50s), heating failure becomes urgent when your household includes: Infants or young children Elderly family members Anyone with respiratory conditions, heart disease, or compromised immunity Anyone recovering from illness or surgery Pets that can’t regulate body temperature well Urgent But Not Emergency: Schedule Promptly These situations need attention soon but don’t require middle-of-the-night service: Heating working intermittently System runs sometimes but not consistently. Uncomfortable but not dangerous in moderate weather. Schedule service for the next available appointment. Reduced heating capacity System runs but can’t maintain set temperature. Layer up and schedule service within a day or two. Unusual noises or smells (not gas) Burning dust smell when first turning on heat for the season is normal. Persistent burning odors, grinding, or banging sounds warrant prompt service but aren’t emergencies unless accompanied by other warning signs. One zone not heating If part of your home isn’t heating but other areas are fine, you can manage temporarily. Schedule service soon but don’t pay emergency rates. Can Wait: Schedule Regular Service Minor temperature inconsistencies Some rooms slightly warmer or cooler than others. Address during regular maintenance. System running more than usual May indicate efficiency issues. Worth investigating but not urgent. Thermostat quirks Programmable thermostat acting up, display issues, or minor calibration problems. Schedule convenient service. Immediate Steps When Your Heat Fails When you realize your heating system isn’t working, follow this sequence: Step 1: Check for Safety Issues Before anything else, verify there’s no immediate danger: Gas odor? → Evacuate and call gas company (see emergency protocol above) CO detector alarming? → Evacuate and call 911 Burning smell or visible smoke? → Turn off system, evacuate if smoke is significant, call fire department if needed Electrical burning smell or sparks? → Turn off system at breaker, don’t attempt to restart If none of these apply, proceed to troubleshooting. Step 2: Try Basic Troubleshooting Many heating failures have simple causes. Check these before calling for service: Thermostat settings: Is it set to “Heat” mode? Is the set temperature higher than current room temperature? Is the fan set to “Auto” rather than “On”? Are batteries fresh (if applicable)? Air filter: When did you last change it? A severely clogged filter can cause system shutdown Replace if dirty and wait 5 minutes before restarting system Circuit breakers: Check your electrical panel for tripped breakers HVAC systems often have multiple breakers (indoor unit, outdoor unit, emergency shutoff) Reset any tripped breakers once—if they trip again, don’t keep resetting Gas supply (gas furnaces): Is the gas valve near the furnace in the “on” position? Are other gas appliances working (stove, water heater)? Outdoor unit (heat pumps): Is it running? Is it covered in ice? (Some frost is normal; heavy ice is not) Is airflow blocked by debris, snow, or ice? If basic troubleshooting doesn’t restore heat, you need professional help. Step 3: Assess the Urgency Consider: Current temperature: How cold is it outside? How cold is your house? Forecast: Is it getting colder or warming up? Household members: Anyone vulnerable to cold? Time of day: Is it 2 PM or 2 AM? Alternative heat sources: Do you have safe backup options? This assessment helps you decide between emergency service (now, at premium rates) or next-day service (more affordable). Step 4: Keep Your Family Warm While waiting for repairs, take steps to maintain warmth: Safe supplemental heating: Electric space heaters (keep 3 feet from flammables, never leave unattended) Fireplace or wood stove (if you have one and it’s properly maintained) Electric blankets and heating pads Unsafe heating methods to avoid: Gas ovens or stovetops (carbon monoxide risk) Outdoor grills or camp stoves indoors (carbon monoxide and fire risk) Generators indoors or in attached garages (carbon monoxide risk) Unvented gas heaters not designed for indoor use Heat retention strategies: Close doors to unused rooms to concentrate heat Hang blankets over windows for extra insulation Use draft stoppers under exterior doors Gather family in one room to share body heat Layer clothing and use blankets liberally Step 5: Protect Your

How Long Do Heating Systems Last? A Lifespan Guide for Summerville Homeowners

How Long Do Heating Systems Last? A Lifespan Guide for Summerville Homeowners Gas furnaces typically last 15–20 years, heat pumps last 10–15 years, and electric furnaces can last 20–30 years with proper maintenance. However, Lowcountry conditions—salt air, high humidity, and long cooling seasons—can shorten these lifespans by several years if equipment isn’t properly maintained. The key factors affecting longevity include installation quality, maintenance frequency, system sizing, and environmental exposure. Knowing your system’s age and condition helps you plan for replacement before emergency failure, budget appropriately, and make informed decisions about whether to repair or replace when problems arise. For heating repair decisions, understanding expected lifespan is essential context. Why Lifespan Matters for Homeowners Your heating system won’t last forever. Understanding its expected lifespan helps you: Plan financially: Replacement costs $5,000–$15,000. Knowing when to expect this expense prevents budget surprises. Make repair decisions: A $500 repair makes sense on a 10-year-old system. On a 20-year-old system? Maybe not. Avoid emergency replacement: Systems that fail in January leave you scrambling. Planning ahead means choosing equipment on your timeline, not under pressure. Maximize efficiency: Older systems cost more to operate. Knowing when efficiency losses justify replacement saves money long-term. The question isn’t just “how long will my system last?” but “how long should I keep it?” Average Lifespan by System Type Different heating systems have different life expectancies: Gas Furnaces: 15–20 Years Gas furnaces are workhorses. With proper maintenance, many exceed 20 years of service. The limiting factors are usually: Heat exchanger: This critical component can crack with age, creating carbon monoxide risks. Replacement often costs more than a new furnace. Electronic controls: Circuit boards and ignition systems fail over time. Efficiency degradation: Older furnaces lose efficiency as components wear. What determines where in the range your furnace falls: Factor Shorter Lifespan (15 years) Longer Lifespan (20+ years) Maintenance Irregular or skipped Annual professional service Filter changes Infrequent Monthly checks, regular replacement Sizing Oversized (short cycling) Properly sized for home Installation Budget installation Quality installation with proper airflow Usage Heavy use, extreme temperatures Moderate use, mild climate Heat Pumps: 10–15 Years Heat pumps have shorter lifespans than furnaces because they work year-round—heating in winter and cooling in summer. That’s twice the operational hours of a furnace. Components that typically limit heat pump life: Compressor: The heart of the system. Compressor failure often means replacement time. Outdoor coil: Exposed to weather, debris, and in coastal areas, salt air. Reversing valve: Switches between heating and cooling modes. Failure affects system function. Refrigerant system: Leaks develop over time, and older refrigerants become unavailable. Lowcountry-specific factors affecting heat pump lifespan: Our climate is simultaneously ideal for heat pump operation and hard on heat pump equipment: Long cooling seasons: Heat pumps run 6–7 months for cooling alone, accumulating wear. High humidity: Moisture accelerates electrical component degradation. Salt air: Coastal and near-coastal areas experience accelerated corrosion. Mild winters: Less heating stress, but year-round operation means no “off season” for recovery. Electric Furnaces: 20–30 Years Electric furnaces have the longest potential lifespan because they’re mechanically simple: No combustion (no heat exchanger to crack) No gas valves or ignition systems Fewer moving parts than heat pumps Heating elements are relatively inexpensive to replace The catch: Electric furnaces are expensive to operate. Many homeowners replace them with heat pumps before they fail, simply to reduce energy costs. Dual Fuel Systems: Mixed Lifespan Dual fuel systems combine a heat pump with a gas furnace. Each component ages according to its type: Heat pump portion: 10–15 years Furnace portion: 15–20 years When the heat pump fails, you can often replace just that component while keeping the furnace. This extends the overall system investment. How Lowcountry Conditions Affect Equipment Longevity Summerville’s climate creates specific challenges for HVAC equipment: Salt Air Corrosion Even 20+ miles from the coast, salt particles in the air accelerate metal corrosion. Effects include: Outdoor unit degradation: Coils, fan blades, and cabinet panels corrode faster Electrical connection corrosion: Creates resistance, heat, and eventual failure Refrigerant line deterioration: Copper lines develop pinhole leaks Mitigation: Coastal-rated equipment with corrosion-resistant coatings lasts longer. Regular cleaning removes salt deposits before they cause damage. High Humidity Our 70–90% average humidity affects equipment in several ways: Electrical component stress: Moisture accelerates circuit board and relay degradation Condensation issues: Improper drainage leads to water damage and biological growth Ductwork concerns: Humidity can affect duct integrity and insulation Mitigation: Proper system sizing ensures adequate dehumidification. Regular maintenance catches moisture-related issues early. Extended Cooling Seasons Summerville’s cooling season runs April through October—sometimes longer. This means: More compressor cycles: Heat pump compressors accumulate wear faster than in northern climates Longer annual runtime: More total operating hours per year Less recovery time: Systems run nearly year-round with minimal downtime Mitigation: Twice-yearly maintenance (spring and fall) addresses wear from both seasons. Mild Winters (The Good News) Our relatively mild winters are easier on heating equipment: Less extreme temperature stress: Systems rarely operate at maximum capacity Fewer freeze/thaw cycles: Less thermal expansion stress on components Heat pumps stay efficient: Temperatures rarely drop below heat pump effective range This partially offsets the challenges of our long cooling seasons. Signs Your System Is Nearing End of Life Age alone doesn’t determine when to replace. Watch for these warning signs: Increasing Repair Frequency The pattern to watch: Year 1–10: Occasional minor repairs (normal) Year 10–15: Repairs becoming more frequent Year 15+: Multiple repairs per year, major component failures The rule of thumb: If you’re calling for repairs more than twice per heating season, your system is telling you something. Rising Energy Bills Older systems lose efficiency as components wear: Dirty or degraded heat exchangers transfer heat less effectively Worn blower motors work harder to move air Refrigerant leaks reduce heat pump capacity Duct leaks worsen as connections age How to spot the trend: Compare your heating costs year-over-year, adjusting for weather differences. A 15–20% increase without explanation suggests efficiency loss. Uneven Heating If some rooms are comfortable while others are too cold or too hot: Blower motor may be weakening Ductwork may have developed leaks or disconnections System may no longer be sized appropriately (after home additions or insulation changes) While ductwork issues can be addressed separately, uneven heating from an

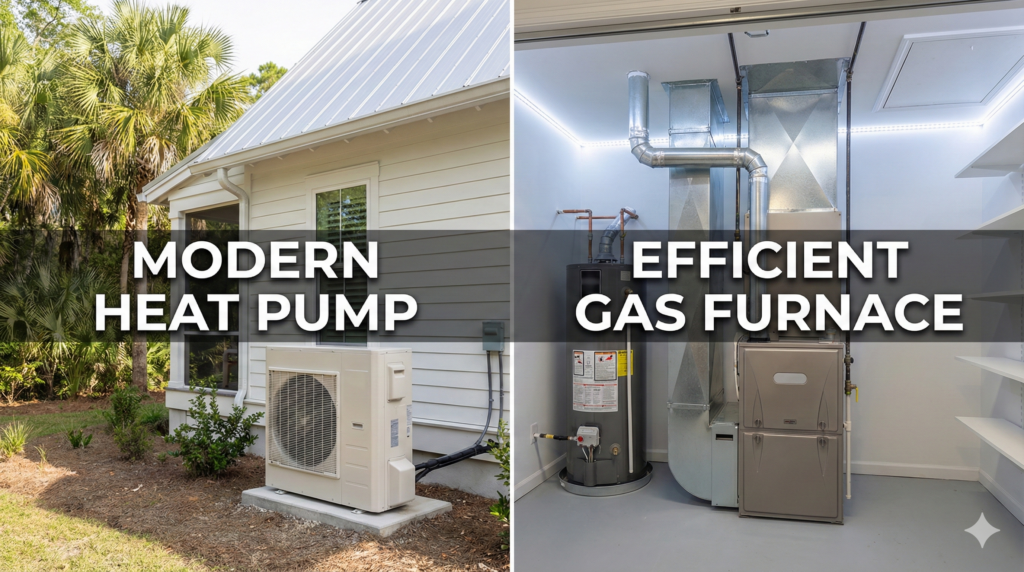

Heat Pump vs. Furnace: Which Is Right for Summerville Homes?

Heat Pump vs. Furnace: Which Is Right for Summerville Homes? For most Summerville homes, heat pumps are the better choice—they provide both heating and cooling, operate more efficiently in our mild Lowcountry climate, and cost less to run than furnaces for the majority of the year. Furnaces make sense primarily for homes with existing natural gas infrastructure or for homeowners who prefer the warmer air output furnaces provide. Many Lowcountry homes use dual fuel systems that combine a heat pump with a gas furnace backup for optimal efficiency across all temperatures. Understanding how each system works helps you make informed decisions about heating repair, replacement, and ongoing maintenance. Why This Comparison Matters in the Lowcountry If you live in Minnesota, the heat pump vs. furnace debate has a clear answer: you need a furnace. Winters are too cold for standard heat pumps to operate efficiently. But Summerville isn’t Minnesota. Our mild winters—with average lows in the mid-30s to low-40s and only occasional dips below freezing—create ideal conditions for heat pump operation. This changes the calculus entirely. Understanding the differences between these systems helps you: Make smarter decisions when your current system needs replacement Know what to expect from your existing equipment Communicate effectively with HVAC technicians Optimize your energy costs year-round Whether you’re troubleshooting a problem, planning a replacement, or just curious about what’s heating your home, this guide breaks down everything Summerville homeowners need to know. How Furnaces Work A furnace generates heat by burning fuel or using electric resistance, then distributes that heat through your ductwork. Gas Furnaces Gas furnaces burn natural gas or propane to create heat: The thermostat calls for heat The gas valve opens and burners ignite Flames heat a metal heat exchanger The blower fan pushes air across the hot heat exchanger Heated air (typically 120–140°F) flows through ducts to your rooms Combustion gases exhaust through a flue pipe to the outside Pros: Produces very warm air quickly Works effectively regardless of outdoor temperature Lower operating costs than electric furnaces (where gas is available) Long lifespan (15–20 years with proper maintenance) Cons: Requires natural gas or propane infrastructure Combustion creates carbon monoxide risk (requires proper venting and detectors) Only provides heating—separate AC system needed for cooling Less efficient than heat pumps in mild climates Electric Furnaces Electric furnaces use resistance heating elements—essentially large versions of the coils in a toaster: The thermostat calls for heat Electric heating elements energize and get hot The blower fan pushes air across the hot elements Heated air flows through ducts to your rooms Pros: No combustion, no carbon monoxide risk Lower installation cost than gas furnaces No gas line required Simple, reliable operation Cons: Expensive to operate (electricity costs more than gas per BTU) Only provides heating—separate AC needed Less efficient than heat pumps Can strain electrical systems during peak demand How Heat Pumps Work Heat pumps don’t generate heat—they move it. Using refrigerant and a compression cycle, they extract heat from outdoor air and transfer it inside. Yes, even cold air contains heat energy that can be extracted. The Heating Cycle The thermostat calls for heat Liquid refrigerant in the outdoor coil absorbs heat from outside air The compressor pressurizes the refrigerant, raising its temperature Hot refrigerant flows to the indoor coil The blower fan pushes air across the warm indoor coil Heated air (typically 90–100°F) flows through ducts to your rooms Refrigerant returns outside to repeat the cycle The Cooling Cycle In summer, the process reverses: The reversing valve switches refrigerant flow direction The indoor coil absorbs heat from inside air The outdoor coil releases that heat outside Your home cools down This dual functionality is a heat pump’s biggest advantage—one system handles both heating and cooling. Auxiliary and Emergency Heat Heat pumps include backup electric heating elements (similar to an electric furnace) that activate when: Outdoor temperatures drop below the heat pump’s efficient operating range The heat pump can’t keep up with heating demand The system runs a defrost cycle You manually select “Emergency Heat” mode Important distinction: Auxiliary heat: Supplements the heat pump automatically when needed Emergency heat: Bypasses the heat pump entirely, using only electric resistance heat Emergency heat should only be used when the heat pump itself has failed. It’s expensive to operate and isn’t meant for regular use. Head-to-Head Comparison Efficiency Ratings Explained Different systems use different efficiency metrics: System Type Efficiency Metric What It Measures Gas Furnace AFUE (Annual Fuel Utilization Efficiency) Percentage of fuel converted to heat Heat Pump (Heating) HSPF (Heating Seasonal Performance Factor) BTUs of heat per watt-hour of electricity Heat Pump (Cooling) SEER (Seasonal Energy Efficiency Ratio) BTUs of cooling per watt-hour of electricity Typical ratings: Standard gas furnace: 80% AFUE High-efficiency gas furnace: 90–98% AFUE Standard heat pump: 8–9 HSPF High-efficiency heat pump: 10+ HSPF What the numbers mean: An 80% AFUE furnace converts 80% of gas energy to heat (20% goes up the flue) A heat pump with 10 HSPF produces 10 BTUs of heat for every watt-hour of electricity Here’s where it gets interesting: heat pumps can exceed 100% efficiency in mild weather because they’re moving heat rather than creating it. A heat pump might deliver 3–4 units of heat energy for every unit of electrical energy consumed. Operating Costs in Summerville Operating costs depend on local energy prices and weather patterns. In the Summerville area: Current approximate energy costs: Electricity: ~$0.12–0.14 per kWh (Dominion Energy) Natural gas: ~$1.20–1.50 per therm Cost comparison for a typical 2,000 sq ft home: System Estimated Annual Heating Cost Heat pump (primary) $400–600 Gas furnace (90% AFUE) $500–700 Electric furnace $900–1,200 Costs vary based on home efficiency, thermostat settings, and weather patterns. Heat pumps typically win on operating costs in the Lowcountry because: Our mild winters keep heat pumps in their efficient operating range most of the time Heat pumps provide cooling too, eliminating the need for a separate AC system Electricity prices in South Carolina are relatively moderate Comfort Differences The systems feel different in operation: Furnace-heated air:

Furnace Not Blowing Hot Air? Here’s What Summerville Homeowners Should Check

Furnace Not Blowing Hot Air? Here’s What Summerville Homeowners Should Check When your furnace runs but doesn’t blow hot air, the most common causes are thermostat issues, a clogged air filter, pilot light or ignitor failure, or a tripped safety switch. Start by checking your thermostat settings and replacing your air filter—these simple fixes resolve many heating problems without a service call. If those don’t work, the issue likely involves your ignition system, gas supply, blower motor, or heat exchanger, which require professional diagnosis. For Summerville homeowners, understanding what’s safe to troubleshoot yourself versus when to call for professional heating repair can save time, money, and frustration on cold Lowcountry nights. When Your Heater Runs But the Air Stays Cold Few things are more frustrating than hearing your heating system running while cold air blows from your vents. The system sounds like it’s working. The thermostat says it should be heating. But your house keeps getting colder. This disconnect between “running” and “heating” is actually helpful for diagnosis. It tells you the electrical components are functioning—the thermostat is communicating, the blower motor is operating. The problem lies somewhere in the heating process itself. Before you call for service, there are several things you can safely check yourself. Some fixes take less than five minutes. Others require professional attention. This guide helps you identify which situation you’re facing. Start Here: The Simple Fixes Before assuming the worst, check these common culprits that homeowners can address themselves: Check Your Thermostat Settings It sounds obvious, but thermostat issues cause a surprising number of “no heat” calls. Verify: Mode setting: Is the thermostat set to “Heat” rather than “Cool” or “Off”? In homes with heat pumps, an accidental switch to cooling mode means the system runs but produces cold air. Fan setting: If the fan is set to “On” rather than “Auto,” the blower runs continuously—even when the heating cycle isn’t active. This circulates unheated air between heating cycles, making it feel like the system isn’t working. Temperature setting: Is the set temperature actually higher than the current room temperature? The system won’t call for heat if it thinks the target temperature is already reached. Battery status: Many thermostats use batteries. Low batteries can cause erratic behavior or prevent the thermostat from communicating with your system. Replace batteries if your thermostat display is dim or blank. Programming check: If you have a programmable or smart thermostat, verify the schedule. Someone may have adjusted settings, or a software update may have reset your preferences. Replace Your Air Filter A clogged air filter is the single most common cause of heating problems—and the easiest to fix. When your filter is clogged: Airflow becomes restricted The system overheats trying to push air through Safety switches trip to prevent damage The furnace shuts down the heating cycle while the blower continues running How to check: Locate your filter (usually in the return air vent or at the furnace itself). Remove it and hold it up to light. If you can’t see light through it, it’s too dirty. The fix: Replace the filter with a new one of the same size. For most homes, filters should be replaced every one to three months—more frequently if you have pets or allergies. Important: If your system shut down due to overheating, it may need a few minutes to reset after you replace the filter. Turn the system off, wait five minutes, then turn it back on. Check Your Circuit Breakers Heating systems typically have multiple electrical connections: A breaker for the air handler/blower A separate breaker for the furnace or heat pump outdoor unit Sometimes a dedicated breaker for the ignition system If one breaker trips while others remain on, your blower might run while the heating components don’t. Check your electrical panel for any tripped breakers related to your HVAC system. The fix: Reset any tripped breakers by switching them fully off, then back on. If a breaker trips again immediately, don’t keep resetting it—this indicates an electrical problem requiring professional attention. Inspect Your Vents and Registers Blocked or closed vents can create pressure imbalances that affect system performance: Make sure all supply vents are open and unobstructed Check that return vents aren’t blocked by furniture or rugs Verify that no one has closed vents in unused rooms (this can cause system-wide problems) While blocked vents usually cause uneven heating rather than complete heating failure, checking them takes only a minute and rules out an easy fix. Furnace-Specific Troubleshooting If the simple fixes didn’t solve your problem and you have a gas or electric furnace, these issues may be the cause: Pilot Light Problems (Older Gas Furnaces) If your furnace is more than 15–20 years old, it may use a standing pilot light—a small flame that burns continuously and ignites the main burners when heat is needed. Signs of pilot light issues: No heat at all from the furnace You can hear the furnace trying to start but it doesn’t ignite Visible pilot light area shows no flame What you can check: Many furnaces have a small window that lets you see the pilot light. If it’s out, you may be able to relight it following the instructions on the furnace’s label. Caution: If you smell gas, don’t attempt to relight the pilot. Leave your home immediately and call your gas company. Gas leaks are emergencies. When to call a professional: If the pilot won’t stay lit after relighting, the thermocouple (a safety device that detects the pilot flame) likely needs replacement. This is a professional repair. Ignitor Failure (Modern Furnaces) Most furnaces manufactured in the last 20 years use electronic ignition rather than a standing pilot light. Common types include: Hot surface ignitors: A ceramic element that glows red-hot to ignite gas Intermittent pilot: An electronic spark that lights a small pilot, which then ignites the main burners Signs of ignitor failure: Furnace attempts to start (you hear clicking or see the inducer fan run) but doesn’t ignite System tries multiple times then shuts down Error codes on the furnace control board (if equipped)

Duct Cleaning After Home Renovation: Why It’s Essential for Your Health and HVAC System